Our Mission

At Precision Laser NW, we provide safe, efficient, and non-destructive laser cleaning solutions for industrial equipment, historic structures, machinery, metal surfaces, and much more. Our advanced laser technology uses ultra-fast nano pulses of light to precisely remove rust, paint, oil, grease, and other surface contaminants—without harsh chemicals, abrasive blasting, or damage to the underlying material. This non-contact method is ideal for sensitive environments, indoor applications, and precision components, making it the perfect choice for preserving the integrity of even the most delicate surfaces.

Why choose us?

1

25X Faster Than Traditional Methods

Laser cleaning works up to 25 times faster than sandblasting, chemical cleaning, or manual scraping.

This incredible speed saves you valuable time and cuts labor costs.

Get more done in less time — without sacrificing quality.

2

Mobile Laser Cleaning Services

Our mobile laser cleaning units bring the power of precision cleaning straight to you.

No complex setups, no delays — just fast, efficient service wherever you need it.

3

Safe and Non-Damaging

Laser cleaning is chemical-free and non-abrasive, meaning it won’t harm delicate surfaces.

No leftover residues, no secondary waste — just a clean, safe finish ready for whatever comes next.

4

Eco-Friendly and Green

Go green with laser cleaning.

No harsh chemicals, less dust, and easy cleanup with a simple vacuum.

Protect the planet — and your workspace — with an eco-friendly surface cleaning solution.

Services We Provide

General Clean Up & Restoration

Maintain a clean environment with our versatile laser cleaning services. From industrial equipment to public spaces, our eco-friendly method efficiently removes contaminants, ensuring surfaces are safe and presentable.

Graffiti Removal

Restore surfaces to their pristine state with our laser graffiti removal. Our method safely vaporizes paint from brick, stone, metal, and glass, preserving the original material and eliminating the need for harsh chemicals.

rust removal

Eliminate surface rust, flash rust, and deep corrosion from metal structures, railings, and marine equipment—no grinding or harsh chemicals required.

Paint Stripping

Strip away failing or outdated coatings from vehicles, metal panels, or architectural elements while preserving the original substrate.

Historical Restoration

Delicately clean centuries-old metals, heritage woodwork, and masonry by removing grime, corrosion, and flaking paint—without harming intricate features.

…And much more!

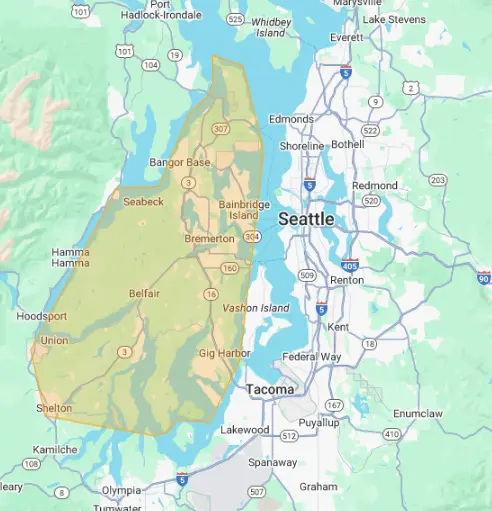

Our Service Area

Areas We Serve: Bainbridge Island, Belfair, Brinnon, Chimacum, Gig Harbor, Hansville, Indianola, Keyport, Kingston, Manchester, Port Angeles, Port Ludlow, Port Orchard, Port Townsend, Poulsbo, Sequim, Shelton, Silverdale, Suquamish, Tacoma, Union, Kitsap County, Jefferson County, Mason County

Frequently Asked Questions

What is laser cleaning and how does it work?

Laser cleaning is a non-contact, eco-friendly method that uses focused laser beams to remove contaminants like rust, paint, graffiti, and oxidation from surfaces. The laser energy breaks down and vaporizes the unwanted layer without harming the underlying material. It’s ideal for delicate, historic, and industrial surfaces.

Is laser cleaning safe for all surfaces?

Yes, laser cleaning is safe for a wide range of materials, including metals, stone, brick, plastic, and composites. Our technicians adjust laser settings to match the material, ensuring precision and protection—even for sensitive or intricate surfaces.

What are the Safety and Environmental Impacts?

Laser cleaning produces minimal waste and doesn’t rely on toxic chemicals, making it a safer option for workers and the environment. Many systems come with integrated vacuum systems that collect particles and fumes, further improving air quality in the workspace. It’s a modern solution that aligns with increasingly strict environmental and safety standards.

How does laser cleaning compare to sandblasting or chemical stripping?

Laser cleaning is cleaner, safer, and more precise. Unlike sandblasting, it doesn’t produce dust or damage surfaces. Unlike chemical stripping, it involves no harsh chemicals or toxic runoff. It’s ideal for environments that require minimal mess and maximum precision.

Can laser cleaning remove heavy rust or multiple paint layers?

Absolutely. Industrial-grade laser systems are powerful enough to remove deep rust, scale, and multiple paint layers from machinery, pipelines, tanks, and structures—without grinding, sanding, or damaging the base metal.

Is laser cleaning environmentally friendly?

Yes, it’s one of the greenest cleaning methods available. Laser cleaning produces no hazardous waste, uses no water or chemicals, and drastically reduces air and surface pollution compared to traditional methods.

How long does a typical laser cleaning job take?

Laser cleaning produces minimal waste and doesn’t rely on toxic chemicals, making it a safer option for workers and the environment. Many systems come with integrated vacuum systems that collect particles and fumes, further improving air quality in the workspace. It’s a modern solution that aligns with increasingly strict environmental and safety standards.

Do you offer mobile laser cleaning services?

Yes! We have fully equipped mobile laser cleaning units that can come to your site—whether it’s a factory floor, construction zone, or historic site. On-site service ensures minimal disruption and fast turnaround.

Is there any surface preparation needed before laser cleaning?

In most cases, no special prep is required. However, we may recommend removing loose debris or ensuring dry conditions to optimize results. Our technicians handle all prep during the initial setup.

How much does laser cleaning cost?

Costs vary based on the size, type of surface, and scope of work. We offer competitive rates and customized quotes. Get in touch with us today for a free, no-obligation estimate tailored to your project.

Where can I find laser cleaning near me for reliable laser rust removal?

At Precision Laser Northwest, we specialize in professional laser cleaning near you, offering advanced laser rust removal solutions that are safe, precise, and eco-friendly. Our cutting-edge technology removes rust, paint, and contaminants without damaging the underlying surface—perfect for automotive parts, tools, industrial equipment, and more. Located on the Kitsap Peninsula, we’re proud to serve local clients with dependable service and top-tier results.

What are the main benefits of laser rust removal compared to traditional methods?

Laser rust removal offers several advantages over traditional techniques like sanding, chemical stripping, or abrasive blasting. It is a non-contact, eco-friendly method that precisely targets rust without damaging the underlying metal. This makes it ideal for delicate components, industrial machinery, and heritage restorations. Additionally, laser rust removal produces minimal waste, reduces labor time, and doesn’t require the use of harmful chemicals, making it a cleaner and more efficient solution.

Why is laser technology a superior choice for graffiti removal on delicate surfaces?

Laser graffiti removal is the preferred method for delicate or historic surfaces because it offers unmatched precision and control. Unlike abrasive blasting or harsh chemical treatments, laser cleaning selectively vaporizes the graffiti without harming the original material underneath—whether it’s stone, metal, brick, or even glass. This non-invasive process is ideal for preserving architectural details and avoiding surface etching, making it the most advanced and conservation-friendly option for graffiti removal.